Our company | Bianchi Angelo

Key Milestones & Dates

Proactively fabricate one-to-one materials via effective e-business. Completely synergize scalable e-commerce rather than high standards in e-services. Assertively iterate resource maximizing products after leading-edge intellectual capital.

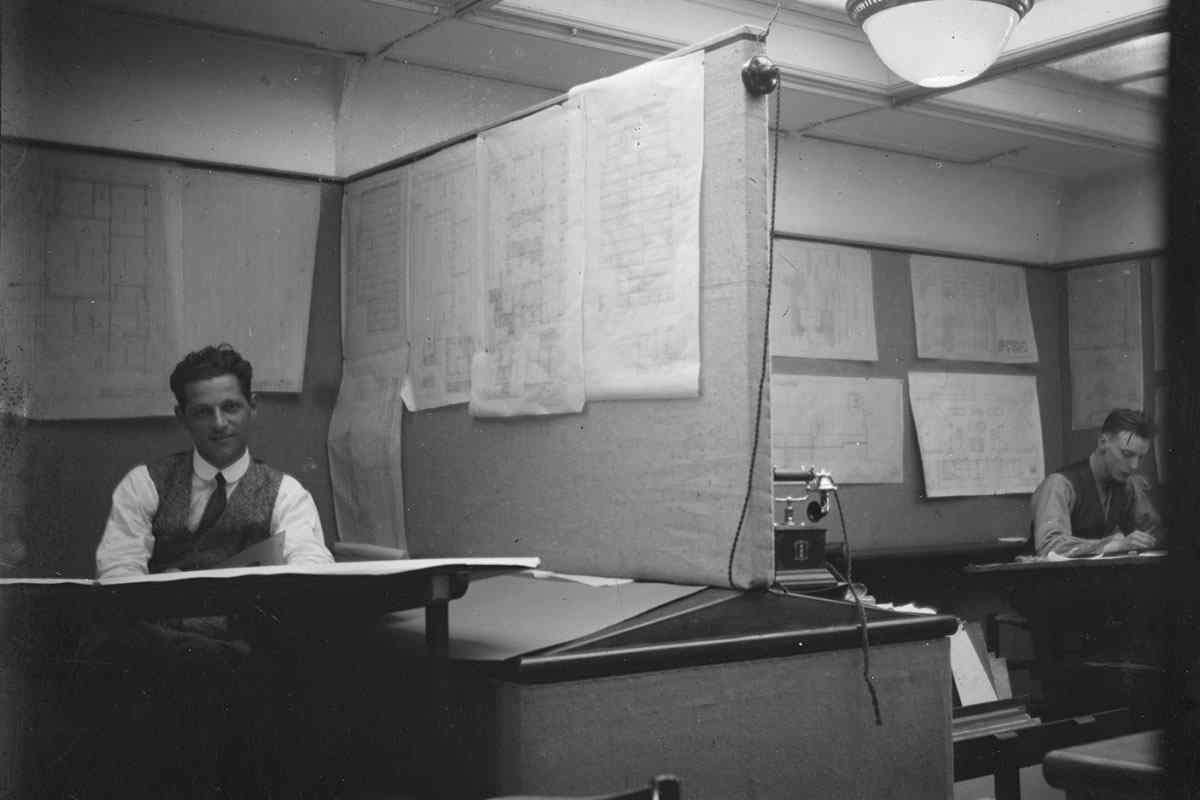

The foundation of “Luigina Nisoli Snc.”

The foundation was followed in 1984 by the acquisition of “Bianchi Metalli Srl”, leader in the marketing of iron and not for turnings.

Plan to Market

Market to Growth

The establishment of “Bianchi Angelo S.r.l.”

The first approval for Enel (National Electricity Board) on socket contacts and plugs.

The second approval for Enel on socket contacts and plugs.

The installation of the first single spindle lathes with number control (Gildemeister).

“Bianchi Angelo L.t.d.” moves to the new site in 2005.

Installation of the first mechanical multi-spindles Gildemeister with automated bar loading Lemca.

Installation of the Trans-bar machine with number control “Buffoli”, capable of reaching up to 55 mm.

Due to the crisis in the metallurgical sector, “Bianchi Angelo S.r.l” presents the procedure of pre-emptive arrangement in continuity in order to preserve their know-how.

“Bianchi Angelo S.r.l” closed positively the procedure of pre-emptive arrangement in continuity 6 months in advance in Bergamo. The company continues its evolution with the acquisition of the new modified alcohol washing machine (IFP), with automatic loading of baskets.

The program Mitutoyo for SPC (Statistical Process Control) was installed. SPC is a method of quality control which employs statistical methods to monitor and control a process. This helps to ensure that the process operates efficiently, producing more specification-conforming products with less waste.

Administrative and operational headquarters

Via Galileo Galilei, 12 – 24053

Company data

Cap. Soc. € 500.000,00 interamente versato

CCIAA Bergamo n. 470652

Reg. Imprese di Bergamo n. 04540200161